OUR SERVICES

Testing, Analysis, and Technical Reporting Services

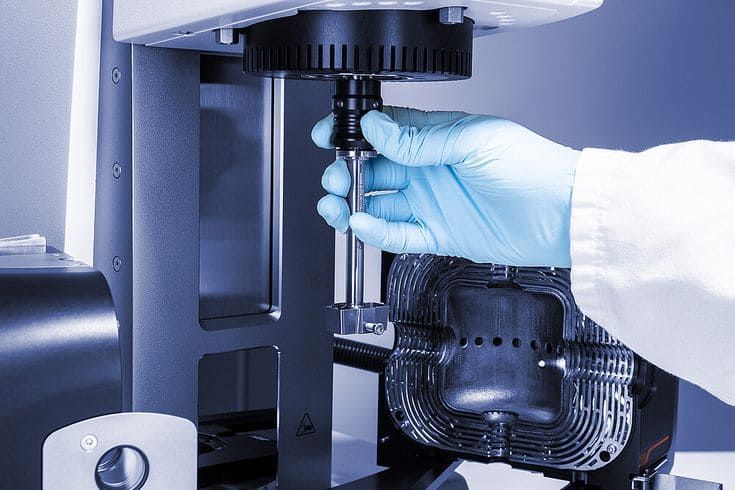

Our Testing, Analysis, and Technical Reporting services enhance product and process reliability through experiments and evaluations in metallurgy and materials engineering. Through our collaborations, we conduct in-depth assessments of material microstructure and performance using comprehensive methods such as metallography, mechanical testing, SEM-EDS, and failure analysis. We transform these findings into clear technical reports supported by actionable recommendations, enabling reliable, data-driven decision-making across all stages from production to design.

- Surface and cross-section examinations using optical and scanning microscopes: microstructure characterization, grain size, phase analyses, decarburization, etc. Microcracks, voids,

- Fracture origin and fracture surface analysis

- Sample preparation procedures (grinding, polishing, and etching)

- Hardness tests (Rockwell, Vickers, Brinell)

- Hardness-depth profiles

- Material strength tests (tensile, impact, fatigue) and comparative evaluation

- Microhardness measurements, analyses for weld/joint areas

- Scanning electron microscope examinations of microstructure, morphology, and composition

- Elemental analysis and frequency distribution using EDS

- Phase identification based on XRD or SEM

- Phase density, phase equilibrium, and phase diagram interpretations

- Interpretation of mechanical behavior with microstructure correlation

- Coating, wear, and surface roughness measurements

- Surface morphology and coating thickness analyses

- Meaningful interpretation of analysis results

- Recommendations for suitability, reliability, and product performance

- Improvement suggestions related to production processes

- Sample acceptance report, test plan, and reporting templates

- Technical reports with graphs, tables, and explanatory captions

- Transparent project updates in terms of cost and time

- Reporting language options in Turkish and English